By Lauriane Lognay

Photos by Lauriane Lognay/Rippana Inc.

This is part one of a two-part series exploring the different types of methods and processes commonly used to create synthetic gemstones.

The gemstone market is saturated with imitations and synthetics. While many believe these lab-grown gems have been around for 30 years at the very most, this is simply untrue. Indeed, synthetics have been observed in jewellery and have infiltrated the market as far back as 1885. While the original creators of these lookalike stones remain a mystery, the first few lab-created gemstones have been traced back to Switzerland. This is why older pieces of jewellery can (and most likely will) contain synthetics: at the time, these gemstones were sold as naturals and were less expensive to purchase.

First and foremost, an important note: if you have any doubts whatsoever as to the nature and/or identity of a gemstone, it is advised you submit it to a reputable lab or gemmologist for analysis. Nothing beats this certification—and nothing builds a reputation better than professionalism and transparency!

That said, the objective of this article is to help jewellers determine what type of lab-grown gem they are dealing with and how it was made. The text will dive a bit deeper than simply ‘synthetics are lab grown’ and, instead, explain a few techniques commonly used to create these stones.

What are synthetic gemstones?

Simply put, synthetics are gemstones created and grown by man. They share the same chemical composition and crystalline structure as their natural counterparts, but have been crafted artificially. (As an aside, this method of creation does not necessarily guarantee a gemstone is ethical; however, this is a discussion best suited for another article.)

To many industry professionals and gemmologists, a synthetic stone looks like a natural gemstone on Botox—it can be hit or miss. In the ‘miss’ category, sometimes a gem’s colour is simply too flawless; other times, the colour change on an alexandrite will be exaggerated and perfect, or the asterism on a star sapphire will be visible even when in the dark with no illumination. These observations make a synthetic easier to detect and subsequently test should they be sold in a dishonest or deceptive manner.

When well done, however, synthetic gemstones can be hard to recognize. Indeed, when compared to their natural counterparts, they can have such similar inclusions and hues that they fool even the most experienced professionals when they are examined with the naked eye. Thus, when an optical effect or propriety seems too good to be true, taking to time to analyze the stone in question at a lab is a safe bet.

Flame fusion (or Verneuil) method (melting process)

One of the most familiar and common processes for crafting synthetic gemstones is the flame fusion method (also known as the Verneuil method in honour of its developer, chemist Auguste Verneuil).

Regarded as the first commercially successful synthetic process, this method is among the least expensive. It is widely used to create synthetic spinel and corundum (i.e. sapphire and ruby), but can also create synthetic rutile and strontium titanate (which are rarely seen on the market).

Flame fusion offers a fairly fast production rate, with crystal growing at a rate of 10 mm (0.39 in.) per hour. The synthetic crystals from this method before cutting are called boules and resemble an elongated cylinder-type crystal.

Due to the internal stress of the structure, the corundum crystals have to be broken/split in two pieces on their length (i.e. the split is done on the optic axis of the boule). They can grow to be about 20 mm (0.78 in.) in diameter and 100 mm (3.9 in.) in length, and can be all colours of the rainbow and beyond, just like natural corundum.

The process is done by dropping the powdered chemical into the rotating crystal seed at temperatures up to 2200 C (3992 F) (this is why it is referred to as a ‘melting process’). As the boule grows from the crystal seed, the base rotates and lowers down.

The chemicals used depend on the colour one is looking to make. For example, obtaining the red needed for synthetic ruby would require some chromium to be added to the aluminum powder.

The inclusions often observed in cut stones include:

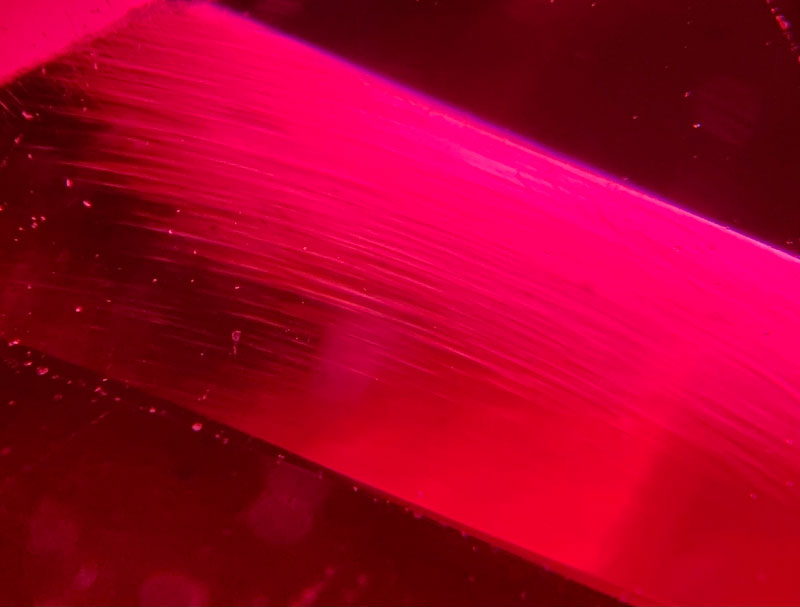

- curved striae (growth lines);

- white-ish crystals (cloudy appearance);

- elongated bubbles perpendicular to the curved striae; and

- small bubbles formed in a cloud.

Spotting and identifying any of these inclusions may help determine if a particular stone is natural or synthetic.

Flux growth method (solution process)

In addition to being one of the more costly processes, the flux growth method is very long and time-consuming, with crystals taking anywhere from two weeks to a year to grow. The equipment required is expensive, but also well worth the investment if done right. This technique can create synthetic varieties of alexandrite, corundum, spinel, and emerald (along with the other beryls). Despite the extra expense, the process is popular because the colours produced are typically better than other synthetic techniques.

Depending on the gemstones desired, the solutions required and the results vary. For the flux synthetic emerald, the growth rate is only about 1 mm (0.039 in.) per month, whereas for corundum, approximately 2 kgs (4.4 lbs) can be obtained in 14 days. The crystals coming out of the melting pot will have the same crystalline growth as their natural counterparts.

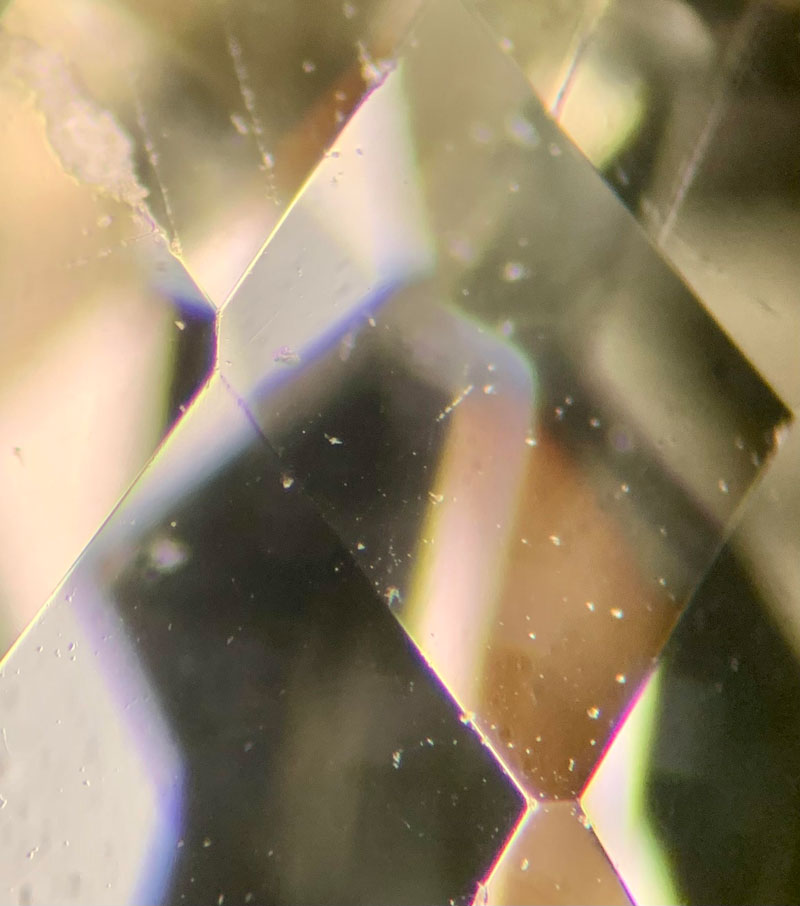

Some inclusions found in flux emeralds and flux corundum include:

- undulating flux veils with a milky yellow-ish or white-ish aspect;

- growth zonings;

- hexagonal platinum platelets from the melting pot (usually black/grey, opaque, and metallic); and

- flux cavities formed in the gemstone.

The refractive index and the density in flux-grown emerald are usually lower than their natural counterpart.

The flux solution is first heated, then the other chemical elements are gradually added to the heated solution. Flux is a solid material that, when melted, dissolves other materials similar to how water dissolves sugar. The synthetic crystals form as the material gradually cools down. The ideal temperature for dissolving the ingredients to form an emerald using this method would be around 800 C (1472 F); for ruby and sapphire, the temperature must be increased to 1300 C (2372 F).

Hydrothermal growth method (solution process)

Similar to flux growth, the hydrothermal growth method is time-consuming and expensive (it is, however, the only method able to successfully create synthetic quartz). Other synthetic gemstones created using this method include emerald (and, less commonly, all other beryls), corundum (sapphire and ruby), and common opal (no colour play and, thus, almost never created).

This growth method is the closest to processes seen for natural gemstones in that the functionality of the machine imitates the conditions in which the gemstones form under the earth’s crust (i.e. through heat and high pressure).

Likewise, the mechanics are the same: a solution is heated, then mixed in and dissolved with other chemicals. The crystal seed grows as the solution cools down. The machine required to grow quartz is larger than the one needed for emeralds and operates at a higher temperature.

On a funny note: for emeralds to form, the silica must be isolated from the other ingredients while the solution heats up. If it is not correctly isolated, the solution will spontaneously produce phenakite crystals, which closely resemble emerald in its chemical composition.

The production rate is about two weeks for a developed crystal—approximately 0.33 mm (0.013 in.) per day, to be precise.

Inclusions found in emerald include:

- ‘dog teeth’ (i.e. growth zonings/patterns);

- two-phase inclusions called ‘nail heads’ (or phenakite crystals);

- white-ish undulating veils; and

- solution remains.

For quartz, however, inclusions are not so easy: there may be none visible, or the synthetic stones may have small ‘bread crumb’ inclusions (i.e. dusty brown or yellow speckles).

The Gilson method (solution/sedimentation process)

Regarded as the closest chemical process to how natural opals form, the Gilson method is, indeed, the only convincing way to create a synthetic opal. These stones demonstrate a clear play of colour and pattern, and can be crafted in white (like the natural Ethiopian opal) or black (like Australian opal).

It was in France in 1974 that the Gilson Company, led by Pierre Gilson Sr., created the three-step process. Some industry professionals do not consider these opals as true synthetics, but, rather, imitations (this is because some of the chemical ingredients used to make the stones are not found in the natural opal, meaning Gilson opals lack synthetics’ required ‘same chemical composition’ as their counterparts). Nonetheless, stones created using the Gilson method are the closest to synthetic opals we have crafted thus far and are seen often enough on the market, making them worthwhile to mention.

Synthetic opals are grown using sedimentation technique. Small microscopic silica spheres are created, which are then finely dispersed in an acidic water solution. The spheres settle in the water and are left for sedimentation process. The method is considerably long and time consuming, taking anywhere from 14 to 18 months to form a fully grown synthetic opal, but produces large plaquettes (or disks) with fantastic colour play. Overall, it is also an expensive process for synthetics, but inexpensive in the grand scheme of opal prices.

Inclusions, unfortunately, are a bit trickier to identify. That said, the synthetic Gilson opal has a play of colour that, unlike its natural counterpart, will not move. In natural opals, the red zone can become green; colour zones can move and shift, making it appear to be constantly in movement; in the synthetic opal, however, colour play and colours stay in the same exact spot. Because the synthetics are well made, however, this difference can be hard to spot.

Another notable inclusion can be spotted on the stone’s side (which, sometimes, is not possible if it is in a closed setting). In synthetic opals, ‘pillars’ of colour can be observed, which are not natural and a good indication of a created opal.

Room for all gems

Synthetics will always have a peculiar place in the natural gemstone market. Buying them for what they are is great and sometimes the only option your clients have, but problems occur when these gemstones are sold as natural and untreated or when clients come in with older jewellery, believing they have rare gems in their possession.

As trusted jewellers and gemmologists, remaining honest about what we sell, informed about what we do, and careful about what we say is paramount to our success in the industry. Like I always say: the more you know, the more prepared you will be to face the everyday life of a jeweller at the bench.

Check out part two of this column here.

Lauriane Lognay is a fellow of the Gemmological Association of Great Britain (FGA), and has won several awards. She is a gemstone dealer working with jewellers to help them decide on the best stones for their designs. Lognay is the owner of Rippana Inc., a Montréal-based company working internationally in coloured gemstone, lapidary, and jewellery services. She can be reached via email at rippanainfo@gmail.com.

Lauriane Lognay is a fellow of the Gemmological Association of Great Britain (FGA), and has won several awards. She is a gemstone dealer working with jewellers to help them decide on the best stones for their designs. Lognay is the owner of Rippana Inc., a Montréal-based company working internationally in coloured gemstone, lapidary, and jewellery services. She can be reached via email at rippanainfo@gmail.com.

Sources

- gia.edu

- Guide des pierres précieuses by Walter Schumann

- gemsociety.org