By Alethea Inns

In any given year, gemmological laboratories screen, test, and analyze millions of diamonds. Given this plethora of data, gemmological laboratories are able to effectively track trends in not only what is coming through the laboratory, but also what is being offered for sale on the market. As such, gemmological laboratories have their finger on the pulse of what is being sold at the jewellery retail level.

One of the most common questions gem labs are asked by clients and industry members alike is, “What do I do about undisclosed laboratory-grown diamonds?”

This is a fair question—especially when it is raised by retailers. After all, these professionals are ultimately responsible for the final disclosure of diamonds and diamond jewellery to the customer. Before going across the sales counter, diamonds must go through multiple processes (including screening and detection, as well as laboratory testing and analysis) to ensure what the customer receives is exactly what the retailer has represented it as.

This article will unpack what jewellery retailers need know about diamond testing and screening equipment—including the differences between certain devices, as well as the basic equipment they can and cannot rely on. We will also discuss the importance of education in this regard, including what base knowledge retailers should have, along with the expertise laboratory-scientists bring to the table.

Finally, we will look at disclosures, including important observations and trends coming out of Gemological Science International’s (GSI’s) laboratory, and the ways in which this information supports the notion that screening, detecting, and disclosing are essential for the health of the gem and jewellery industry.

Why?

Let’s kick things off with a baseline question: Why are detection and disclosures so important to the health of our industry?

The answer, simply put, comes down to the most important word in the work of jewellers, gemmologists, and diamantaires: trust.

Consumer confidence is key to our industry’s success. If customers do not trust jewellery, they’ll buy something else. Jewellery commemorates life’s most important moments, and it is our job to earn consumer trust every day.

Of course, this is not the responsibility of one segment of the industry—it’s up to all of us. The most important element of this is disclosure, and ensuring any given product is accurately represented throughout the supply chain.

In 2021, global laboratory-grown diamond production was estimated at 10 million carats, which is the equivalent of between eight to 10 per cent of natural diamond production for the same year.1-3 Statistically, and based on production observations by GSI, one in 10 melee diamonds is laboratory-grown. This means if you have a piece of jewellery with more than 10 melee, it is very likely at least one of the stones is laboratory grown.

Diamond scientists come across undisclosed laboratory-grown diamonds daily—and in increasing quantities and qualities. Indeed, we truly see it all: natural diamonds in laboratory-grown jewellery, simulants, treated diamonds, and more. In mounted jewellery, due to the unique challenges of testing, we are seeing more unexpected results and instances of mixing.

What do I do?

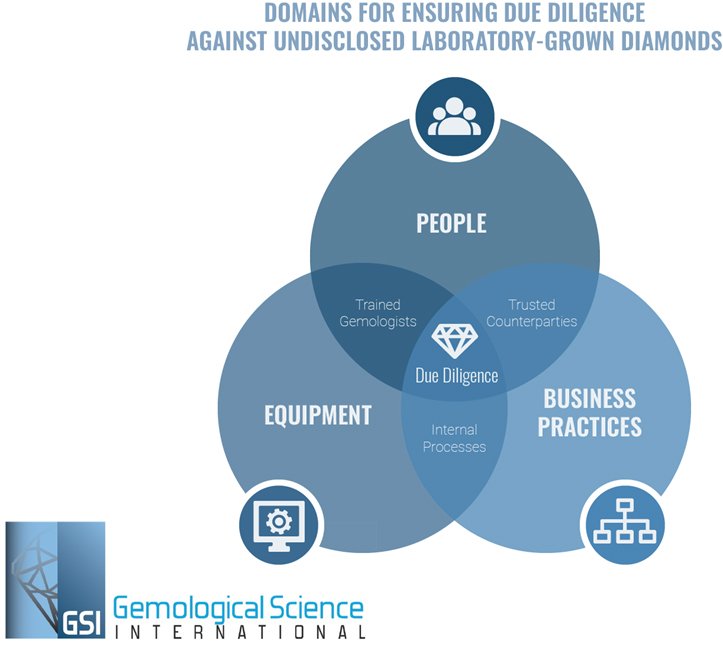

To best protect yourself and your jewellery business from the threat of undisclosed diamonds (and ensure proper detection practices are in place), it is advisable to take a three-fold approach:

- Equipment

- Throw away traditional methods and old testers

- Have more than one piece of testing or screening equipment

- People

- Education, education, and more education

- Ask questions and get assurances (a.k.a. CYB)

- Business practices

- Have internal processes in place

At the centre of this three-fold approach is the “sweet spot” where you can say you have done the due diligence to protect yourself, your business, and your customers (Figure 1).

Equipment

When it comes to screening and detection at store level, equipment is among the most frequently discussed and debated topics.

Most gemmological testing relies on passing light through the gemstone to obtain spectra, or to have a good view of the pavilion to see growth patterning and other characteristics. However, when a diamond is mounted, all bets are off. Gemmologists are left to find creative ways to obtain spectra and observe the stone. Bezel settings are, of course, the most challenging.

Not only do we have to do the testing on mounted goods, but we must ensure all our processes are non-destructive. Life would be much easier if we could just pop diamonds out the mounting and pop them back in.

Some pieces of jewellery are extremely complex to test, even for the most skilled gemmologist.

Throw away traditional methods and old testers

When it comes to today’s necessities for detection, hand-held conductivity probes that use thermal or electrical conductivity are no help, as laboratory-grown and natural diamonds have the same thermal and electrical conductivity.

Likewise, traditional gemmology does not always work either, given:

- Inscriptions can be forged or polished off easily.

- Size is not an indication, as large laboratory-grown diamonds are plentiful on the market—further, as growth technology improves, the size of these stones continues to increase.

- Strain patterns under crossed polarized filters can show the internal strain a diamond has undergone; however, these are not conclusive (though they can display different patterns of internal strain based on their growth, there can be overlaps in appearance).

- A lack of (or presence of) inclusions is not diagnostic: Laboratory-grown diamonds have inclusions, natural diamonds can be inclusion free, and vice versa.

- Even inclusions themselves can be misleading, as there can be overlaps in their appearance. Surface-reaching inclusions (e.g. fractures, feathers) can occur in both, as can healed fractures, minute black inclusions, and graphitization. Likewise, twinning wisps and mineral inclusions, which are historically only found in natural diamonds, can be mimicked by linear inclusions across plane lines in chemical vapour deposition (CVD) diamonds, while the metallic flux inclusions in diamonds grown using high-pressure, high-temperature (HPHT) methods could confuse a gemmologist without the proper experience.

Have more than one piece of testing or screening equipment

Given visible features are not diagnostic, advanced equipment is required to distinguish the non-visible features of any diamond being screened or tested.

Before we discuss why it is essential to have more than one piece of testing or screening equipment, it is important to distinguish the difference between “screening” and “testing” as it applies to equipment and processes. While these two terms are often thought to be interchangeable, they are not.

While testing looks at individual stones, screening happens in bulk and does not provide a definite answer as to the growth origin of a diamond. This means screening does not reveal if a diamond is “natural” or “lab grown”; rather, it provides you with an answer of “pass” or “refer.” The former (“pass”) generally means a diamond is natural, but the result may not tell you if it is treated. A “refer” result, however, could suggest any number of things. It could be the diamond is natural, but with low nitrogen (either Type IIa or IAB), or it may have H3 centres which are throwing off the readings. Sometimes a diamond of a low or unusual colour (or with odd phosphorescence or fluorescence) yields a “refer,” while other times even a stone’s cut can confuse the screening machine.

When jewellery professionals ask, “What piece of equipment should I get?” the hope, of course, is there is a single instrument on the market, capable of screening, testing, and doing everything else we might need it to do. Unfortunately, every device has some sort of limitation, weakness, or blind spot. When it comes to testing and screening, there are no “fix-all” solutions. This is not to say the devices on the market are not good—many are, but with limitations. It is essential to understand those limitations.

Most desktop devices are screening equipment, which means they only yield a “pass” or “refer” result. This only tells you what a diamond could be and not what it actually is. As such, it behooves jewellers to have more than one tool for detection—preferably a suite of devices that complement each other by filling in the limitations of the other device.

So, which instrument should you buy? When making this choice, consider:

- What you will be testing (loose, mounted jewellery, or both)

- Testing volumes (single items or large batches)

- Manual or automated outputs

- Detection of simulants (i.e. moissanite, cubic zirconia)

- The required skillset of the operator

- Qualitative or quantitative results

When a medical doctor gives you a diagnosis, they never run one test—even if many tests are required, more often than not, there is a resolution or cure for your ailment. Diamond diagnostics should be thought of in a similar way.

People

People and relationships are essential for doing your due diligence in mitigating the risk of undisclosed laboratory-grown diamonds.

Education, education, and more education

Typical screening devices use a combination of spectra and luminescence reactions. The science itself is solid, but the additional factors (detailed above) can still contribute to a less-than-100 per cent accuracy rate for a device.

In truth, equipment is only as good as its operator, which is why working with gemmologists who have specific, current knowledge of detection is of the utmost importance. Detection itself is a complex multi-step process. To complicate matters further, equipment gets outdated as growth technologies evolve. Not only does the equipment have to keep up, but so do the experts working with it. This notion scares a lot of jewellers—especially since retailers have so much on their plates in addition to worrying about undisclosed, laboratory-grown diamonds.

Jewellery retailers are becoming increasingly keen to ensure their sales team has the information needed to better educate customers. Front-facing staff may not need to have gemmologist-level expertise, but base knowledge is essential for proper disclosures at the point of sale.

While educating and properly onboarding staff can be costly, it is certainly a worthwhile investment. Your team is on the front lines, communicating with customers. They need to be confident, knowledgeable, and enthusiastic about your product lines.

It is not uncommon for sales team members to get flustered when discussing laboratory-grown diamonds with customers. From a managerial perspective, it helps to practice some talking points with your team. Ensure you are up to date with the latest news and discoveries in laboratory-grown diamond detection by reading articles in trade and gemmological journals.

Additionally, provide your sales team with ongoing education. Offer refresher courses, role-play disclosure conversations, and share technical knowledge of differences and similarities between laboratory-grown and natural diamonds. They may never need to describe the difference between HPHT and CVD growth processes to a customer, but it is helpful for them to have this knowledge in their back pocket.

Finally, make sure you and your team stay updated on consumer protection laws related to disclosures and advertising as these pertain to laboratory-grown diamonds.

From the technical perspective, it is also essential for gemmologists to stay up to date on the evolution of laboratory-grown diamond growth techniques and technologies, keep abreast of emerging testing, screening, or detection techniques and equipment, and network across organizations. While the latter point may sound counter-intuitive because of business competition, the reality is the trust of our industry simply does not exist in the vacuum of our own individual businesses. Indeed, “co-optition” (collaboration and competition) is mutually beneficial. It is in your best interest to collaborate across the jewellery industry to stay abreast of laboratory-grown diamond screening and detection. It is almost impossible to be successful on this front entirely on your own.

Ask questions and get assurances

Relationships are important. Obtain assurances from your suppliers and work with trusted vendors. Do not be afraid to ask the questions you need to about their own processes for ensuring goods are free of undisclosed laboratory-grown diamonds.

It is not uncommon for large retailers to require diamond jewellery suppliers go through independent third-party processes of screening and testing. Many smaller or independent retailers do not believe they have the scale to require the same, but the reality is we are all in the same industry, and most retailers are buying goods from the same places, suppliers, and sources. It is more likely than not that a supplier is already going through the process for a larger retailer; so, for smaller retailers, requesting it or requiring this is not too much to ask.

This begs the question: Is it on the retailer to commit to ensuring business processes and supply chain uphold the integrity of the product? The answer is, simply, it has to be. Retailers are the last set of hands on the product before the customer gets it.

Business practices

Diamonds must go through multiple processes, including screening and detection. At the gem-lab level, testing and analysis is a key part of those processes for retail customers, as this assures the product the customer receives is exactly as it has been represented.

Have internal processes in place

For many jewellery retailers, enlisting gem-nerds who work in laboratories (like yours truly) to perform screening and detection can take the pressure off. Letting trusted diamond scientists and gemmologists perform this specialized work lets retailers and suppliers focus on delivering to their customers.

Consider business operations processes:

- Examine your workflow. Identify any places mixing between natural and laboratory-grown diamonds can happen in your pipeline, both internally and externally.

- Build third-party testing into your internal processes (including having goods vetted by a third-party independent laboratory).

- Maintain inventory control. This includes establishing dedicated spaces for laboratory-grown and natural goods, incorporating tagging and tracking to identify natural versus laboratory-grown goods, and using clear packaging to differentiate the two.

Final thoughts

It is important to note the mixing of natural and laboratory-grown diamonds is most often inadvertent and unintentional. Jewellery, like any other product, goes to third parties for value-add manufacturing steps. As a result, chains of custody are broken; there is room for error, especially with a product so small.

You may have seen documentaries or news features, claiming laboratory-grown diamonds are not distinguishable from natural diamonds. The jewellery industry often comes under attack by journalists and filmmakers, especially during major retail buying seasons (e.g. winter holidays, Valentine’s Day, Mother’s Day). This fear-mongering narrative sells stories and is top of mind for the general public.

The reason for the difficulty (not impossibility) of separation is because laboratory-grown diamonds have the same chemical, optical, and physical characteristics of their natural counterparts. This has opened up the jewellery industry to false claims, asserting it is impossible to separate natural and laboratory-grown diamonds. Rest assured: Gemmological laboratories perform this task every day—on a large scale—for all types of diamonds and diamond jewellery. Separation of diamond by growth origin can be done successfully. Focusing on your people, processes, and equipment can set you up to confidently assure any customer who may have doubts or questions.

Alethea Inns, BSc., MSc., GG, is a fellow of the Gemmological Association of Great Britain (FGA). Her career has focused on laboratory gemmology, the development of educational and credentialing programs for the jewellery industry, and the strategic implementation of e-learning and learning technology. Inns is chief learning officer for Gemological Science International (GSI). In this role, she leads efforts in developing partner educational programs and training, industry compliance and standards, and furthering the group’s mission for the highest levels of research, gemmology, and education. For more information, visit gemscience.net.

Alethea Inns, BSc., MSc., GG, is a fellow of the Gemmological Association of Great Britain (FGA). Her career has focused on laboratory gemmology, the development of educational and credentialing programs for the jewellery industry, and the strategic implementation of e-learning and learning technology. Inns is chief learning officer for Gemological Science International (GSI). In this role, she leads efforts in developing partner educational programs and training, industry compliance and standards, and furthering the group’s mission for the highest levels of research, gemmology, and education. For more information, visit gemscience.net.

References

1 Dhanraj L, Roshan D. Lab-grown diamonds market by manufacturing method (HPHT, CVD), by size (below 2 carat, 2-4 carat, above 4 carat), by nature (colorless, colored), by application (fashion, industrial): Global opportunity analysis and industry forecast, 2021-2031. Allied Market Research, 2023 March; https://www.alliedmarketresearch.com/lab-grown-diamonds-market-A13694

2 Linde O, Epstein A, Kravchenko S, Rentmeesters K. Brilliant Under Pressure: The Global Diamond Industry 2020–21. Bain & Company, 2021 February. https://www.bain.com/insights/global-diamond-industry-2020-21

3 Lab-grown diamonds, MVI Marketing, LLC (THE MVEye), 2022 Dec.; https://www.themveye.com/statistic-details.php?id=2