An eye on the Cloud: What does the next wave of CAD innovation look like?

by emily_smibert | August 11, 2017 11:16 am

[1]

[1]By Hemdeep Patel

“First to mind when asked what ‘the Cloud’ is, a majority respond it’s either an actual cloud, the sky, or something related to weather.” ~ Citrix Cloud Survey Guide (August 2012)

Though this is possibly true when the topic of cloud computing comes up in everyday conversation, “the Cloud” has revolutionized nearly every aspect of our lives. Though the Cloud might seem a far away and unrelated subject when it comes to the jewellery industry, I would suggest the power of this non-weather related technology is starting to push CAD into a new phase of commerce.

The Cloud is more accurately defined as cloud computing, which loosely describes any type of computing or digital storage used or accessed using the Internet. The actual computing and storage takes place in large computer server facilities which may be located kilometres or even an ocean away.

For a vast number of jewellers, the Cloud serves as the perfect partner when trying to store large amounts of data in a safe and easily accessible place. For this reason, cloud computing has caught the imagination of software providers and engineers. When software is placed in the Cloud, it can be accessed by a wider audience of users without the need to download or store a copy of the program on a computer. This is a powerful shift in computer technology because users can access this program on mobile phones, laptops, or desktop computers without needing to worry the technology they are using to interact with the software won’t be powerful enough since all of the heavy-lifting computation is done by the Cloud.

Now, how does this fit into the jewellery industry, and more specifically, how does this relate to CAD?

Simply, it will start to change the way designers create models and how they monetize the files they have built.

[2]

[2] [3]

[3]

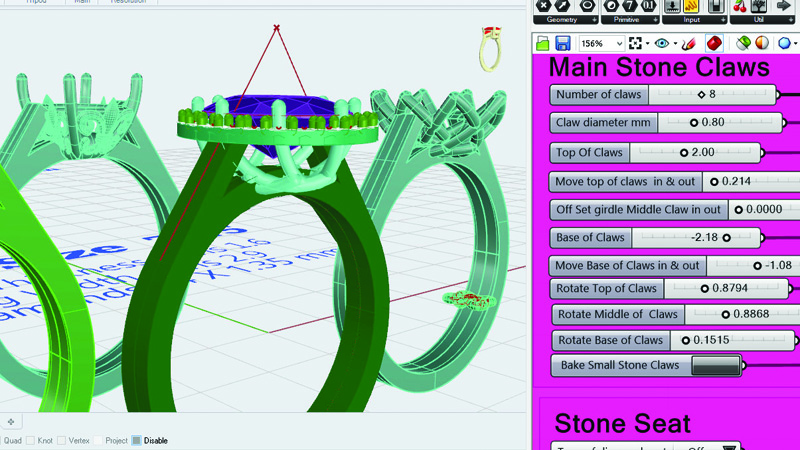

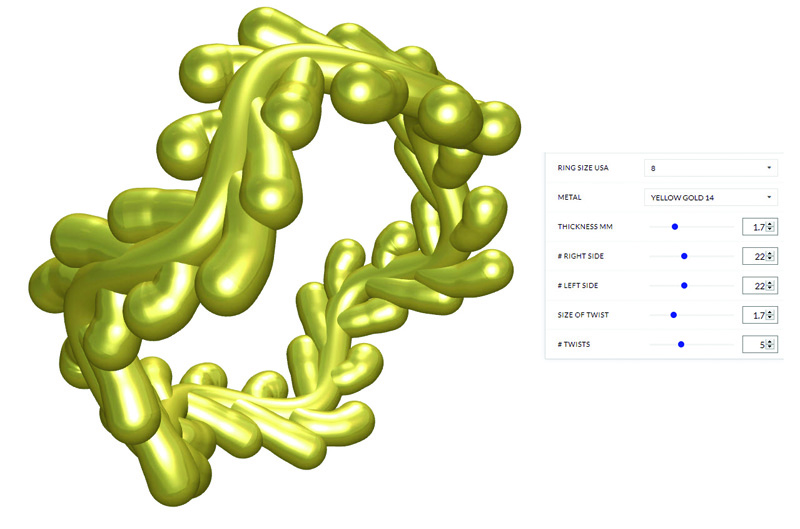

Parametric design reloaded

Back in July 2016, I wrote about parametric design. Broadly speaking, this is where design meets coding. Cloud computation is the perfect vehicle to launch large-scale parametric design. In that article, “Evolutionary theory: A paradigm shift in technology, growth, and engagement through CAD/CAM ,” I described some of the growing trends in CAD software and their applications. One of the areas I highlighted was parametric design.

“This allows users to build CAD designs using simple logic code and varying input values. Take a cup, for example. The software allows you to break down its design features into any number of key design elements, including height, the thickness of the inside wall, degree of curve on the upper edge, and angle of flare from the bottom to the top. To build parametrically, each of those features is related to an input field, which is entered in a number box. Quite simply, the designer types in all the values regarding each of the cup’s key design features. With a couple of simple key strokes, the user can build their own cup.”

[4]

[4]With the power of cloud computation, parametric design has now made its way onto an e-commerce platform. Developers of this new design concept have told this author that with the power of cloud computation, they are able to deliver user-generated real-time designs. With the use of a series of tabs and input boxes, users can quickly design, change, and redesign models over a desktop, tablet, or mobile phone.

As with any potential business endeavour, greater amounts of available information and varying options lead to a better revenue stream.

Therefore, these parametric designs can be further coded so users can be given estimated weights of the piece in a metal of their choice. In addition, more robust features could provide customers an estimated stone weight and varying prices for the finished piece with a variety of gemstone and diamond qualities.All of this would be provided in real time at the user’s leisure.

Though this can never replace the CAD custom design business model, it does create a business opportunity for someone creating a branded line of jewellery, where key features of the brand are already set and are unmodifiable, but the variation in stone size, shape, or a number of other variables are changeable by the user.

So what can I do with this?

Every CAD designer faces one particular problem: How to build a revenue stream with the hundreds or even thousands of models occupying hard drives?

[5]

[5]To date, there isn’t a software leader in this area, as there would need to be a wide range of software developments to allow smooth transition to the Cloud. Though cloud computing could start to provide solutions to these idle files, a new platform would have to feature the following:

- User-friendly interface, with minimal effort needed to make files live;

- Editability allowing users to make changes to the design without needing to recreate the file.

The creation of a new online platform is an important first step to helping designers showcase their work to new audiences.

This new business model is similar to traditional casting house brass model boards. Currently, there are some available online platforms helping designers exhibit online catalogues, where new customers can browse, and make basic changes to stone types, the alloys used, and obtain quotes. But it is the ability for the user to design and create parametric designs on jewellery that would require a new revolution in software design since the designer would have to build the original core design parametrically within CAD.

Even though this revolution is yet to arrive, one can safely assume it is on the front burner for the major software players in the jewellery industry.

Hemdeep Patel is head of marketing and product development of Toronto-based HKD Diamond Laboratories Canada, an advanced gemstone and diamond laboratory with locations in Bangkok, Thailand, and Mumbai, India. He also leads Creative CADworks, a 3D CAD jewellery design and production firm. Holding a B.Sc. in physics and astronomy, Patel is a third-generation member of the jewellery industry, a graduate gemmologist, and vice-president of the Ontario chapter of the GIA alumni association. He can be contacted via e-mail at hemdeep@hkdlab.ca or sales@creativecadworks.ca.

- [Image]: https://www.jewellerybusiness.com/wp-content/uploads/2017/08/bigstock-Cloud-computing-22747763.jpg

- [Image]: https://www.jewellerybusiness.com/wp-content/uploads/2017/08/IMG-20170619-WA0013.jpg

- [Image]: https://www.jewellerybusiness.com/wp-content/uploads/2017/08/IMG-20170619-WA0037.jpg

- [Image]: https://www.jewellerybusiness.com/wp-content/uploads/2017/08/Grasshopper-2.jpg

- [Image]: https://www.jewellerybusiness.com/wp-content/uploads/2017/08/image-1.jpg

Source URL: https://www.jewellerybusiness.com/features/an-eye-on-the-cloud-what-does-the-next-wave-of-cad-innovation-look-like/