Divide and conquer: GS Labs aims for consistency in a subjective world

by charlene_voisin | December 1, 2012 9:00 am

By Jacquie De Almeida

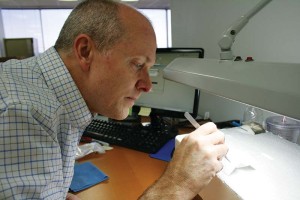

[1]

[1]Three colourless synthetic diamonds sit on Sam Barbuzzi’s desk, though none are part of a parcel submitted for grading. Instead, the Gemesis-produced 40-pointers were sourced by one of Barbuzzi’s suppliers. Why? He wanted a closer look.

“The synthetics just came into the office yesterday, and I haven’t had a chance to play around with the pen yet to see if it actually works,” says Barbuzzi, co-owner of GS Laboratories (GSL), which provides diamond and jewellery grading to the trade and consumers. “But I’m going to look at the stones very closely and do all the things we would normally do. We want to make sure we’re prepared if we come across any lab-grown diamonds.”

The pen he’s referring to is actually a low-cost laser device claiming to show indicators that a colourless diamond is synthetic in origin. It’s new on the scene, spurred by the discovery of undisclosed colourless lab-created diamonds earlier this year by the International Gemological Institute (IGI).

Staying informed of technological developments like colourless lab-grown diamonds is a must for GSL, which has offices in Toronto, Dallas, and four in India: two in Mumbai’s Opera House district and the Bharat Diamond Bourse, one in Chennai, and one in Pune. The India offices are key not only in the sense they are located where 90 per cent of the world’s diamonds are cut and polished, but also because they allow GSL to service its biggest client, which happens to be a major U.S. chain. At the Mumbai office, diamonds are graded by GSL’s staff before being shipped to North America, ensuring the stones meet the client’s program requirements. It also means costs are kept low on customs fees that would be incurred should the product not be up to par and have to be sent back.

Changing with the times

[2]

[2]The road to Dallas, and subsequently India, began 28 years ago after a chance encounter between Barbuzzi and GSL co-founder, Andrew Tatarsky, at a north Toronto shopping mall. Tatarsky was working an antiques appraisal event when Barbuzzi stopped by. They quickly struck up a conversation and soon realized they had both attended St. Michael’s College School. An opening for a gemmologist at Tatarsky’s office led to the two working together, and it wasn’t long before they ventured off on their own to start what would later become GS Labs.

When the opportunity to take on a major U.S. chain as a client presented itself in 2003, Barbuzzi re-located to Texas. Three years later, the first of GSL’s offices in India opened its doors. All the company’s locations are certified against the International Organization for Standardization (ISO) 9001:2000, Quality Management Systems.

The grading business has evolved greatly since 1985, when Barbuzzi and Tatarsky started out. In the last few years, however, it’s the development of gem-quality synthetic diamonds that has garnered a great deal of attention. Although there was some concern when coloured synthetics first came on the scene, the fact they were so vibrant in colour made them easy to pick out without too much trouble.

Colourless lab-grown diamonds, however, are a different story, with concerns over disclosure and maintaining consumer confidence being voiced even before they could be produced in any real quantity. It wasn’t long, however, before undisclosed stones were being discovered. First came IGI’s discovery in May of 600 colourless synthetics in a single parcel. A month later, the Gemological Institute of America’s (GIA’s) office in Hong Kong uncovered 10 more. In both cases, the stones were grown using chemical vapour deposition (CVD).

While Barbuzzi says vigilance is necessary, he quickly points out the chances of coming across a single undisclosed synthetic are pretty slim. All lab-created diamonds are Type IIa stones, which constitute less than three per cent of the total gem-quality diamonds in the world.

“The number of synthetic diamonds out there is minute compared to the millions of natural stones,” Barbuzzi explains. “Because of what’s happened in the last few months, however, I think everyone is more aware of what is going on, as well as more aware of whom they’re dealing with and the assurances they receive.”

Although using advanced gemmological equipment is the only way to positively identify Type IIa diamonds, Barbuzzi points out there are a few things retailers can do. One, they can look at the stone under long-wave fluorescent light. He says synthetics tend to fluoresce green for the most part, as opposed to blue, as is the case of natural stones. Also, lab-grown diamonds created via high pressure, high temperature (HPHT) can sometimes include metallic flux inclusions that can be detected with the use of a simple magnet. Both methods do not conclusively determine a stone is lab-grown, but they may raise red flags. As Tatarsky puts it, “Your Spidey sense goes off and you look for other signs”¦ [But] I’m not sure all this is as scary as everyone makes it out to be. Synthetic coloured gemstones have been around for years. Eventually, science catches up”

Barbuzzi agrees, adding he predicts someone will develop a simple and inexpensive piece of equipment to positively identify synthetic diamonds in the next five years or so. His advice? Don’t panic and refrain from buying on the open market.

A matter of opinion

[3]

[3]In an industry where trust is paramount, news of a grading scandal tends to shake even the most cynical. One earlier this year at HRD Antwerp, complete with allegations of inappropriate conduct involving four diamond graders and three unnamed companies, sparked intense outcry, with many calling for the firms to be identified. The incident is an extreme example of how grading can be manipulated, but it reignited debate surrounding acceptable grade differences.

As Jewellery Business contributor Mark T. Cartwright pointed out in his August column, a variance of a single grade rarely makes a difference in price. It is also not unusual for labs to differ in opinions even though they are all using the Gemological Institute of America’s (GIA’s) grading system. As Cartwright puts it, they are all speaking the same language, but using different dictionaries.

“Grading is subjective,” says Barbuzzi, pointing out that no two of the six sets of GIA master colour stones in the Texas office are alike. “If I take a diamond that was graded by GIA in California and take the same diamond to GIA’s office in Mumbai, I may get a difference of opinion. Who’s right and who’s wrong? Neither. They’re both right, because it is all a matter of opinion and you’re allowed a certain leeway on either side.”

Tatarsky says most labs—GSL included—strive for consistency among their graders, and that smaller offices like theirs might be better able to meet that goal. Bigger labs, however, can have upward of 200 graders; getting everyone to grade the same way can be challenging.

“There are times when I think our offices have better consistency than other major labs only because we have fewer people to actually tighten into the way we grade diamonds,” he explains.

For the most part, however, Tatarsky says retailers and diamond wholesalers get a sense over time how a particular lab will grade a diamond. Still, market reality dictates that grades naturally evolve; what used to be an SI2 say, 20 years ago is not an SI2 today. Staying aware of grading trends is paramount.

“I don’t want to be grading diamonds today the same way I did 30 years ago if GIA isn’t,” Barbuzzi says. “I have to keep up with the way GIA is doing it. It reinforces what I do. If there is a difference of one grade, that’s allowable. If it’s two, three, or four, then we have a problem. And we’ve never had a problem.”

Every three months, GSL’s biggest U.S. client randomly selects stones the lab has graded and sends them to GIA. Barbuzzi says it’s a method of quality control he welcomes, as it helps ensure GSL’s gradings remain in line with the rest of the industry. He also likes to do his own homework. Leaving his loupe at home, he regularly drops by local retailers to check out what their prices are like, and compares the grading reports to the merchandise.

“I have to know what my customer’s competition is doing,” he says, adding he asks to use a magnifier rather than a loupe to not alert staff to his background. He says that for the most part, what he sees and what is on the report match up.

Overall, most jewellers understand that legitimate grading variations are the norm, given the subjective nature of the process. Some equipment exists that can determine colour grade, although it cannot properly read stones in the I, J, K, and L range. But what if technology existed one day that could consistently grade all four Cs. Would labs become obsolete?

“Well, you’d still need someone to work the machines,” Barbuzzi says.

- [Image]: http://www.jewellerybusiness.com/wp-content/uploads/2016/02/Opener1.jpg

- [Image]: http://www.jewellerybusiness.com/wp-content/uploads/2016/02/Image8a.jpg

- [Image]: http://www.jewellerybusiness.com/wp-content/uploads/2016/02/Image4_4x6.jpg

Source URL: https://www.jewellerybusiness.com/features/divide-and-conquer-gs-labs-aims-for-consistency-in-a-subjective-world/