Can I make metal moulds using a mill?

Well, yes and no. Metal does not ‘peel back’ like rubber does. Instead, you have to construct a metal mould using ‘building blocks’ to get the desired model. The real question is, how many metal moulds do you need a year? If your answer is not that many, you may want to outsource the job to a company specializing in this area. I wish all of us were selling thousands of one design. We would all be driving better cars.

Let’s look at the pros for adding a milling system to your jewellery store. First, it can be very inexpensive to run—wax costs pennies and optional extended warranties are reasonably priced. Second, wax can be recycled at low temperatures and can be easy to cast. In addition to being great for anything requiring text like school rings, as well as flat objects, bangles, and belt buckles, mills can also produce very smooth surfaces, which also makes it easier for cleaning up platinum casting.

With the pros, come the cons. Milling machines can cut only one design at a time, unless they are cutting flat items that can be grouped together or bands on a tube of wax. Some mills do not hollow out, which means the operator may have to cut the design in several parts to clear away excess wax.*

If you have a bench jeweller on staff, the mill may be right for you, as he or she can touch up the wax piece before casting. This allows you to spend less time creating the fine details in CAD, saving hours of computer time.

One very important point about purchasing a mill. Milling machines require a tool path called ‘G-code.’ Some companies offer a complete package at a higher cost that includes CAD software, an automatic G-code generator, and a mill. Although you can purchase these components for less from separate companies, you may have to contact them individually to diagnose a problem and fix it.

Read the fine print

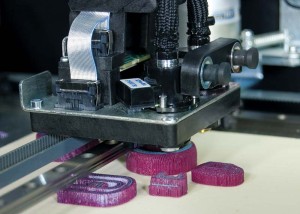

If a milling machine is not suitable to your operation, you may want to consider a 3-D printer. As its name implies, this machine ‘prints’ the wax. The correct terminology for the process is stereo lithography or rapid prototyping (RP). Our industry often refers to a printer as a ‘grower,’ which is fitting, since the machine builds layers of wax one at a time using jets, lasers, or a projector. Compared to CNC, rapid prototyping is relatively new, although the technology has greatly improved in the short period it has been available. Smaller units introduced in the last year can range in price from $10,000 to $25,000.

What about resolution in a printed mould?

Resolution has always been a concern with RP machines. Jewellers require a finer surface than, say the car or toy industries. However, new resins combined with wax are helping to create smoother surfaces, along with smaller microns (i.e. thinner layers).

Rapid prototyping machines for fine jewellery production tend to cost around $18,000, but can be as much as $250,000 depending on volume. Most companies with two or more CAD operators would likely lean toward a larger-capacity machine, which starts at about $48,000 and can produce more than 15 items in a single build time. Smaller machines costing less than $25,000 can produce up to eight engagement rings at a time, which is suitable for a one-man operation. Bangles or large ‘rapper’ type pendants would need to be farmed out to a wax service centre. Build times range depending on the model’s height, although the type of printer you purchase is more of an influencing factor. Some printer companies have created machines with larger build platforms, but tend to run slower. On the other hand, some manufacturers have opted for smaller build areas with faster print capabilities.