Sustainable sparkle: The environmental impacts of mined versus lab-grown diamonds

Energy use

Saleem mentions there are variations in energy use among mines and lab-grown producers depending on location. Beginning with lab-grown producers, to understand the energy used in creating lab-grown diamonds, one must examine the two methods employed—HPHT and CVD. HPHT is a process that converts carbon into a diamond through high pressure and temperature. CVD diamonds are created by using a microwave beam to deposit carbon-rich gas onto a silicon or diamond surface. (This information is derived from the synthetics and treatments portion of the Gemological Institute of America’s (GIA’s) ‘Diamonds & Diamond Grading’ course.)

According to Saleem, HPHT requires fewer ingredients and is faster, whereas CVD allows producers to grow diamonds over a larger surface and better control chemical impurities. It also does not require high temperature. Figure 1 shows the kilowatt hours per carat (kWh/ct.) of two gem-quality lab-grown diamond producers—Apollo Diamond and Gemesis—as well as some details of the production process. However, it is important to note both these companies have been acquired or renamed and current information could be very different.

In an interview, John Hassard, owner of Edgecombe Abrasives (a company that supplies industrial equipment using lab-grown diamonds), explained the variations in energy use between HPHT and CVD depend on several variables, including type of product, yield, grades and applications, type of HPHT press (cubic versus belt), and type of reactors. Both processes require uninterrupted power sources for their production cycles, which can take anywhere from 30 minutes to several days, depending on the target product. HPHT can produce more diamonds per cycle, but with CVD, you can control the quality of the product, which is important for diamonds used in jewellery. Scalability and purity are the major contributors to energy use in lab-grown diamond production. High quality or purity utilizes more energy and is costly.

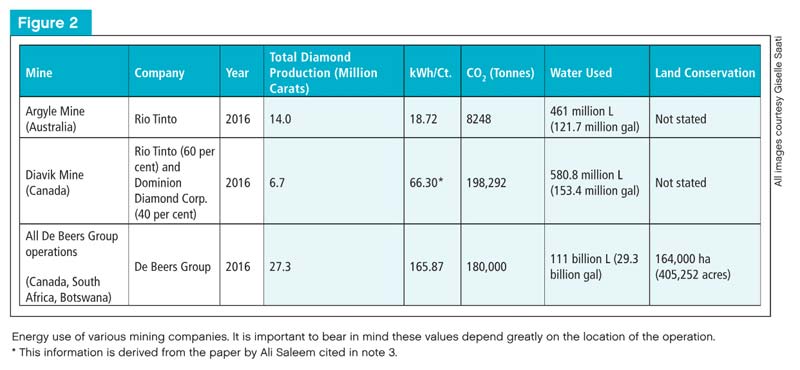

Figure 2 shows the kWh/ct. of certain mining companies. There are two important factors to note. First, this value varies greatly depending on location—the Argyle mine in Australia uses 6.7 to 18.72 kWh/ct., while the Diavik mine uses 66.30 kWh/ct. One reason for this, as Saleem points out, is the fact most Canadian diamond mines are found in remote locations in the Northwest Territories and thus need to produce electricity from diesel fuel. Currently, 77 per cent of De Beers’ energy comes from fossil fuels, a number it aims to reduce using wind farms. (For more, see De Beers Group’s Socio-economic Impact Report, produced by Ernst & Young in 2016.) However, although wind farms are a great source of renewable energy, they pose a threat to wildlife such as bats and birds.

The second important factor is the quantity of carats produced. Mining companies produce millions of carats per year, well outpacing lab-grown diamond producers. Also, it takes days and even weeks to produce larger-carat lab-grown diamonds. There is no data available on the quantity of diamonds lab-grown producers are creating overall, but the Diamond Foundry says it produces 100,000 carats per year, which is significantly less than diamond mines. This begs the question: if lab-grown diamond producers were to pump out the same quantity of diamonds as mining companies, would they be as energy efficient? Could they possibly match or surpass the amount of energy diamond mining companies are using? The issue of transparency and the quantity of diamonds produced could change lab-grown diamond producers’ positive image.