It’s all in the detail

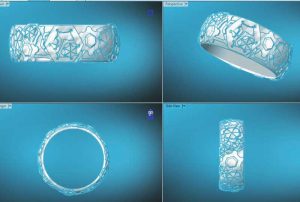

Dana Grund of Grund Designs in Halifax recently asked me to create a CAD design for a men’s wedding band featuring snowflake details, which we then printed and cast in platinum. While the printer did capture some of the snowflakes’ fine detail, Dana went over each one with a graver. Just like Mother Nature, no two snowflakes were the same. I was so impressed with the finished picture he sent me, I asked if I could use it in this article. Dana came back with these interesting points:

Dana Grund of Grund Designs in Halifax recently asked me to create a CAD design for a men’s wedding band featuring snowflake details, which we then printed and cast in platinum. While the printer did capture some of the snowflakes’ fine detail, Dana went over each one with a graver. Just like Mother Nature, no two snowflakes were the same. I was so impressed with the finished picture he sent me, I asked if I could use it in this article. Dana came back with these interesting points:

“The use of CAD as a means to a semi-finished blank is pretty key for me. In the case of the snowflake band, just getting the main shapes symmetrical and at different elevations would have been a nightmare. If I tried to render all the facets I cut in with the graver, it would have been too time-consuming and the piece would have lacked some of its soul.”

When speaking with jewellers at trade shows, I often find many of them are under the same impression that purchasing one software program (CAD) and one output machine (CAM) is all that’s needed. But take a look at your tool box at home. I’m sure it’s full of different kinds of tools, such as pliers or a wrench. Each one is appropriate for a specific task, although I have to admit

I have used the handle of a screwdriver as a hammer when I am too lazy to get one. As Travis Serio, a programmer for Gemvision, likes to say, “When we develop a new tool for our software, we often find everyone is quick to use it for everything when the best tool for the job could be one you already have.”