Zeroing in on diamond weight calculations

by charlene_voisin | July 1, 2013 9:00 am

By Mark T. Cartwright

[1]

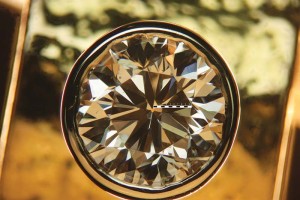

[1]In the previous column, we looked at how tiny errors can add up to significant problems when dealing with many small stones. This time, we’ll look at the calculations and adjustments that might be necessary when examining diamond centre stones.

Whenever we evaluate a piece of jewellery with a centre stone, the carat weight is usually a significant value element. Rarely are we afforded the luxury of being able to physically weigh the stone, and we’re left with a couple of alternatives: we accept someone else’s word for the weight or we perform volume calculations. If we choose the former option, we need to realize it is an extraordinary assumption that could jeopardize our credibility. If we choose the latter, we’re also putting our credibility on the line and will need to be certain to exercise due diligence.

A weighty issue

[2]

[2]In general, there are four ways in which we are able to decide the weight of any stone: weigh it with a scale or balance, accept the word of a third party, estimate the weight, or calculate it using standardized volume formulae. On those rare occasions when we’re able to physically weigh a stone, it’s important to know the accuracy of the scale or balance we’re using and to that end, regularly scheduled calibration and maintenance are musts. If one lacks standardized, precision weights for calibrating a scale, it is good to get in the habit of using diamonds of known weight to verify that one’s scale is accurate.

This brings us to the next method: accepting the word of a third party. To use a stone of ‘known weight’ as a way of checking the accuracy of our own scales, we have to be willing to believe the scales at the gemmological laboratory issuing the grading report are accurate. Laboratory reports are becoming increasingly common, and while often a blessing for the appraiser, they present additional concerns. It’s too easy to simply accept the documents as ‘gospel’ and move on with the appraisal, at least if we have no bias in favour of or against the lab issuing the paperwork. Mistakes can happen, documents can be altered, and forgeries are becoming more of a concern. The concept of due diligence requires that to the best of our ability, we verify the information before we rely upon it. The Uniform Standards of Professional Appraisal Practice (USPAP) Ethics Rule and just good appraisal practice require we disclose our reliance on third-party documents. Such disclosure isn’t about dodging our professional responsibility or potential liability—we can’t. The point is to make users of the document aware of how we reached the value conclusion so they can decide how much credibility it warrants.

The final two methods of deciding a stone’s carat weight can be intertwined and the terms are sometimes mistakenly interchanged. Estimation and calculation aren’t the same, but there may be times when an estimate is required as part of a calculation. As an example, if one measures the diameter of a round brilliant to be approximately 4.1 mm, the stone’s ‘estimated weight’ could be stated as ‘one-quarter carat.’ On the other hand, if it is impossible to directly measure its depth, it may become necessary to resort to ‘sight estimation’ techniques to determine the total depth to complete a volume calculation. The weight is still a calculation, but it was partly derived from an estimate. However, I’m getting ahead of myself. In essence, an estimated weight presumes many unknown factors and may have a fairly wide margin of error. A calculated weight may also include certain presumptions, but it should have a much narrower margin of error. In either case, it’s good practice to include in the report what we believe the margin of error to be.

A little math, anyone?

[3]

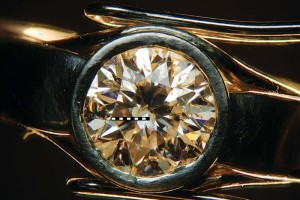

[3]The formulae we rely on for weight calculations are based on volume and specific gravity. For some gems, such as diamond, the specific gravity is relatively consistent, although the style of cutting and variations in proportion details can significantly influence the stone’s volume. For a standard round brilliant diamond, the general formula for calculating weight is usually given as: (average diameter in mm)² X (total depth in mm) X 0.0061. There are a few assumptions built into that formula requiring us to make adjustments for any specific diamond.

For instance, depending on the stone’s size, one with a slightly thick girdle may require a one to five per cent adjustment, a thick girdle may necessitate three to six per cent, and a very thick to extremely thick girdle may need as much as a five to 12 per cent addition to the calculation. Smaller stones will require the larger adjustment percentages. With experience and practice, sight estimation of girdle thickness can yield credible results, but direct measurement of the girdle is usually more accurate. In addition to girdle thickness, deviations in crown angle, crown height, culet size, and shape irregularities may potentially require weight adjustments.

[4]

[4]Sometimes sight estimation techniques are necessary to have the data required to calculate the weight. A large percentage of the diamonds I examine are mounted in closed-back settings that preclude the possibility of direct measurement of the total depth. Unless the prongs extend above the height of the stone, I can normally place the base of my digital micrometer flat on the diamond’s table and extend its rod to the lowest point of the girdle. I make note of this measurement (crown height + girdle thickness) and proceed to sight estimation of the pavilion depth percentage. Many of us will recall that technique from our gemmology courses, but here’s a quick refresher. With our microscope at 10 to 15X zoom, we look through the diamond’s table at the pavilion for the reflection of the junction of the star facets and the table. Sometimes moving the needle’s tip across that junction makes the ‘bowtie’s’ reflection easier to spot on the opposite side of the pavilion.

Centring the culet in the table, we estimate the distance from the culet to the bowtie in relation to the table’s corner. If the bowtie reflection is one-quarter the distance to the corner of the table, the pavilion depth percentage (PDP) is approximately 41 per cent. If it is one-third, then 43 per cent PDP; half is 44.5 per cent, two-thirds is 45.5 per cent; and three-quarters is 47 per cent. And if the reflection is at the edge of the table, the PDP is approximately 48 per cent. Interpolation is often necessary to achieve greater accuracy.

Once we have estimated the pavilion depth percentage, we can convert it into a millimetre measurement by multiplying it by the average diameter. Finally, we add that dimension to the crown height + girdle thickness measurement previously recorded to arrive at the approximate total depth dimension we need to apply the formula. With practice, it is possible to achieve a margin of error of less than three per cent for the weight calculation. I often rehearse this technique using mounted diamonds with open-backed settings and those with a grading report from a lab I trust. Unfortunately, this method is only applicable to round brilliant diamonds; fancy shapes require a different approach.

Practice makes perfect

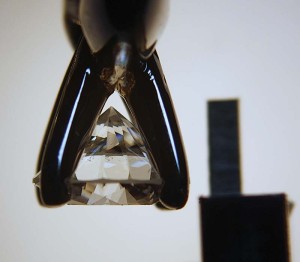

[5]

[5]A second method for arriving at a total depth measurement is one I’ve described as ‘indirectly direct.’ This technique requires the stone’s culet or keel-line is visible and its table unobstructed. I use only dark-field or direct lighting from below the diamond, place a diffusion filter over the well of my microscope, and raise the microscope head to accommodate my hands. Placing the base of a digital micrometer flat on the table of the stone, I lower the rod until I can see it below and behind the pavilion’s silhouette. Looking through only one eyepiece to reduce the effect of parallax, I stabilize the shadow’s image and try to keep the view precisely parallel to the table’s surface. I then raise the micrometer’s rod slowly until it is even with the culet’s silhouette.

This method provides a direct reading of the total depth measurement without the need for sight estimation. Further, it can be applied to fancy shapes, as well as round brilliants.

[6]

[6]Steady hands, constant checking for parallel, and plenty of practice can yield surprisingly accurate results. In general, I find my margin of error for diamonds smaller than 7 mm is in the three to five per cent range. I tend to have less reliable results on larger stones because of depth of field issues that blur the simultaneous view of the culet and the micrometer’s rod without adjusting the focus.

As appraisers we face many challenges, and intended users of our reports should be made aware of those that could significantly affect the credibility of our conclusions. How we determine the carat weight of primary stones certainly falls into that category. Equally important is our opinion of the margin of error. I arrive at my presumed margin of error by tracking my accuracy with diamonds of verified weight and dimensions in similar mountings. If you master these techniques and practice with known samples, you may be surprised by the level of accuracy that is possible. Whether we achieve a one per cent or a 10 per cent margin of error, the users of our reports should understand the extent to which they can rely on our results.

[7]Mark T. Cartwright, ISA CAPP, ICGA, CSM-NAJA, GG (GIA) is president of The Gem Lab, I.C.G.A., an independent American Gem Society (AGS)-accredited gem laboratory. He has been a jewellery designer, goldsmith, gemmologist, and appraiser for more than a quarter century. Cartwright can be contacted via e-mail at gemlab@cox-internet.com[8].

[7]Mark T. Cartwright, ISA CAPP, ICGA, CSM-NAJA, GG (GIA) is president of The Gem Lab, I.C.G.A., an independent American Gem Society (AGS)-accredited gem laboratory. He has been a jewellery designer, goldsmith, gemmologist, and appraiser for more than a quarter century. Cartwright can be contacted via e-mail at gemlab@cox-internet.com[8].

- [Image]: http://www.jewellerybusiness.com/wp-content/uploads/2015/12/radiant-diam-yg-ring.jpg

- [Image]: http://www.jewellerybusiness.com/wp-content/uploads/2015/12/bezel-diam1.jpg

- [Image]: http://www.jewellerybusiness.com/wp-content/uploads/2015/12/bezel-set-diamond-scale3.jpg

- [Image]: http://www.jewellerybusiness.com/wp-content/uploads/2015/12/bezel-diam2-w-scale.jpg

- [Image]: http://www.jewellerybusiness.com/wp-content/uploads/2015/12/micrometer-silhouette.jpg

- [Image]: http://www.jewellerybusiness.com/wp-content/uploads/2015/12/ring-sideview.jpg

- [Image]: http://www.jewellerybusiness.com/wp-content/uploads/2014/12/Mark-Cartwright.jpg

- gemlab@cox-internet.com: mailto:gemlab@cox-internet.com

Source URL: https://www.jewellerybusiness.com/features/zeroing-in-on-diamond-weight-calculations/