Scintillating silver: The other white metal

by carly_midgley | February 13, 2018 2:53 pm

By Llyn Strelau

[1]

[1]Too often overlooked, silver enjoys a long history and many possible applications. Its use in jewellery, coinage, and objects has been referenced in historical records going back at least 8000 to 10,000 years. Next to gold, it is the most important of the precious metals.

Looking back

Early civilizations initially worked with rare alluvial silver nuggets, as well as the naturally occurring alloy called electrum (which also had traces of copper and other metals). Silver mining followed as the ancients discovered how to separate pure silver from the other metals in these alloys. It is still possible to find cabochons cut from black or white quartz with veins of native silver running through the stone. They make attractive jewellery, especially for the men’s market.

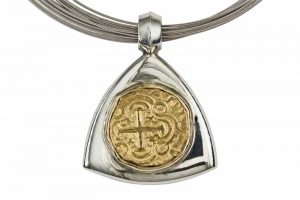

Silver coinage is probably the earliest use of the metal. It is interesting to note in the Roman Empire, there was massive inflation, and the government gutted the silver content of its coinage from more than 95 per cent to 40 per cent and even less by the empire’s end. However, silver coinage is still popular today, albeit more often for collector’s coins than currency due to the lower cost and higher durability of other nonprecious alloys.

Exploring alloys

Pure silver is one of the whitest metals. It is strong, malleable (i.e. able to be rolled or beaten into very thin sheets without fracture), and ductile (i.e. able to be formed by elongation without cracking).

Pure silver is, for most purposes, too soft to craft durable articles. Therefore, various alloys are used instead. The most common is sterling silver (92.5 parts pure silver, usually with copper making up the balance). This creates a stronger alloy while still retaining good workability.

[2]

[2]Photos courtesy Llyn L. Strelau

The one downside of alloying copper and silver is oxidation. Copper reacts with sulphur in the environment to form sulphur oxides, which appear grey to black on the surface as tarnish develops. However, this surface tarnish is easily dealt with, either by polishing on a buff or using one of the wide range of available silver polishing products.

A greater problem is during production of sterling silver items, the metal is heated, and fire scale—a tough layer of copper oxides—is brought to the surface. If not removed, this will remain as a stain on the otherwise bright, polished surface. There are various coatings that can be applied prior to heating to reduce fire scale. Any that remains must be removed using abrasives and polishing compounds.

Fortunately, in recent years, new proprietary alloys have been developed. Some are very resistant to the bane of fire scale and much less prone to tarnishing in the future. They are complex blends of silver with small amounts of copper, tin, germanium, chromium, tantalum, titanium, gold, or platinum group metals added, among others. For the most part, these alloys can be worked with traditional methods, but some do require special protocols for annealing and soldering to maintain their properties. If you use them, be sure to check with your supplier for specific instructions on how to best work with them to avoid problems.

[3]

[3]I used one of these alloys to make the spaceship ornament pictured later in this article. After casting, the metal was rather soft, and it was tricky to retain the accuracy the project required. However, the tarnish resistance the alloy provided once the piece was finished was a bonus, and once we figured out its specific qualities, fabrication was successful.

The alloy required a lower annealing temperature compared to standard sterling and also retained heat longer. Initially, we had issues with the larger sections warping, and this could have been avoided by being more careful with heating and cooling. Soldering proved to be more similar to working with gold, because the heat from a torch did not dissipate as quickly as with copper-based alloys. It was also more fragile when at soldering temperature, so we had to be careful not to move it or touch it with tweezers until it had cooled slightly.

It’s important to check the web for information on whichever new alloy you are using. The manufacturers and suppliers have very good resources that can save you a lot of grief.

Versatile and timeless

[4]

[4]Silver’s inherent malleability and ductility make it very suitable for making both jewellery and elaborate holloware and cutlery. Sadly, many beautiful collections of ancestral sterling silver flatware, tea sets, and other objects have been sold for silver scrap in recent years. Modern lifestyles don’t appear to fit with housewares that require the amount of care (i.e. handwashing and occasional polishing) silver requires. Sure, stainless steel can go in the dishwasher—but old stainless simply looks like old steel, while old sterling silver develops a rich and beautiful patina only this metal can achieve.

Silver jewellery has a long historical tradition, having been made using techniques still employed today. Originally, silver was beaten into thin sheets and decorated with repousse or applied ornamentation such as granulation. It was cast using the lost wax process. The intricacy and beauty ancient craftspeople achieved with relatively primitive tools is humbling in this era of laser welders and computer-aided design (CAD).

Today, we automatically think of setting diamonds in platinum or white gold. When diamonds first became popular in jewellery, however, they were typically set in silver to better showcase their white brilliance. To provide greater strength, these silver settings were backed with yellow gold. Of course, silver does tarnish when exposed to sulphur in the environment, and these older settings needed to be polished at intervals. However, there is a gentle luminosity to antique gold-backed diamonds set in silver. The metal takes a back seat and lets the diamonds shine. When it became possible to work platinum, even it was initially backed with yellow gold, honouring tradition.

Modern silver

When I first began my jewellery career, I—like many of my colleagues—worked exclusively in silver. I could not afford gold and learned how to deal with both the advantages and problems inherent in the metal. This turned out to be excellent training. If you can work successfully with silver, gold and platinum will, for the most part, be far less of a challenge.

Silver, due to its relatively low cost, can be used to create jewellery that has more mass/weight without breaking the bank. This has made it very popular in recent years as the world economy has faltered. Many talented designers have added collections of silver jewellery to their lines. Some pieces are entirely sterling, while others use silver as the base of the piece and accent this with smaller quantities of gold, platinum, or palladium as contrast.[5]

[6]

[6] [7]

[7]

[8]

[8]Deliberately oxidized surfaces are very popular, transforming this property of classic sterling silver into an advantage. Surface treatments are especially effective when applied to recessed areas of a design. This maximizes the contrast and will give visual depth to engraved or textured surface details. There are several methods of blackening silver, but most often, it is done via the application of liver of sulphur (basically potassium sulphide) to a prepared and cleaned surface.

Liver of sulphur typically comes in small chunks, which must be broken up and mixed with hot water. Take care to avoid breathing the powder while working with it—the rotten egg smell will discourage close contact! It should be stored in a dark environment, since it is light sensitive and will degrade over time. There are also other related chemicals available. It can be difficult to achieve a uniform colour with liver of sulphur, and several applications may be required, with cleaning and light abrasion between coats.

[9]

[9]A matte surface tends to take the oxidation better than polished surfaces. My friend Alishan Halebian from California has a master’s touch with the application of blackened surfaces with smooth and consistent colour. He contrasts this surface with bold yellow gold gem-set ornamentation.

One can also electroplate silver with black rhodium to give an even deeper, richer colour, and while I do not personally like to use it, white rhodium is often electroplated over silver to prevent tarnishing. I find the rather chrome-like appearance is artificial-looking, and of course, over time it will abrade away and the piece will require replating. Some commercial silver jewellery is given a thin rhodium plating to prevent tarnish while sitting in the showcase. For greater durability, it could be plated with nickel first to seal the surface, then rhodium for the bright white colour.

An alternative to rhodium plating for standard copper-containing sterling silver involves heating the piece with a torch to bring the copper in the alloy to the surface. Putting it in the pickle will then remove the copper oxide. Repeat this process until the piece doesn’t turn black. This method is called depletion gilding, since it depletes the copper surface and leaves a thin layer of bright white pure silver that is very slow to tarnish.

Good as gold

[10]

[10]As mentioned, silver looks very well when combined with gold. Rich 18- or 22-karat yellow gold provides maximum contrast, but one can use pink and green gold for different effects. When a client brought in a yellow gold reproduction of a bear motif plaque by Bill Reid, the master West Coast Canadian artist, I designed a surround in sterling silver engraved with complementary sun and bear claw motifs to create a substantial belt buckle.

For many years, Jewels by Design has provided service award rings for a Little League baseball organization. As the league is a nonprofit group, we were able to keep the price affordable by making the base ring from silver, with the addition of an 18-karat yellow gold insert with the club’s crest and a baseball ‘diamond’ inset and blackened with liver of sulphur.

Silver is also the traditional gift for 25th anniversary celebrations. A few years ago, a client requested two pendants to celebrate this milestone. He also wished to incorporate family birthstones. My solution was to make a sterling silver book and corresponding slipcase. The book, worn by the husband, opens to reveal the couple’s names engraved on the pages. The cover of each pendant is engraved with a Celtic tree of life motif, and the slipcase (for the wife) is set strategically with the birthstones (the parents at the ‘root’ and the children in the branches).

Silver linings

Silver has sometimes been relegated to being only a step above costume jewellery, and in fact there are rather a lot of insubstantial, poorly made silver items in the marketplace. In the hands of talented designers and craftspeople who understand the attributes (and limitations) of the metal, however, silver has a solid place in our industry. Offering both good value (i.e. attractive pricing) and inherent beauty, it well deserves its status as the ‘other’ white metal.

[11]Llyn L. Strelau is the owner of Jewels by Design in Calgary. Established in 1984, his by-appointment atelier specializes in custom jewellery design for local and international clientele. Strelau has received numerous design awards, including the American Gem Trade Association’s (AGTA’s) Spectrum Awards and De Beers’ Beyond Tradition—A Celebration of Canadian Craft. His work has also been published in Masters: Gemstones, Major Works by Leading Jewelers. Strelau can be reached via e-mail at designer@jewelsbydesign.com.

[11]Llyn L. Strelau is the owner of Jewels by Design in Calgary. Established in 1984, his by-appointment atelier specializes in custom jewellery design for local and international clientele. Strelau has received numerous design awards, including the American Gem Trade Association’s (AGTA’s) Spectrum Awards and De Beers’ Beyond Tradition—A Celebration of Canadian Craft. His work has also been published in Masters: Gemstones, Major Works by Leading Jewelers. Strelau can be reached via e-mail at designer@jewelsbydesign.com.

- [Image]: https://www.jewellerybusiness.com/wp-content/uploads/2018/02/Alishan-flower-rose-cut-bangle.jpg

- [Image]: https://www.jewellerybusiness.com/wp-content/uploads/2018/02/Antique-Russian-brooch-silver-backed-gold-front-view.jpg

- [Image]: https://www.jewellerybusiness.com/wp-content/uploads/2018/02/Ancient-greek-silver-coin-set-in-titanium-and-gold-pendant.jpg

- [Image]: https://www.jewellerybusiness.com/wp-content/uploads/2018/02/Silver-Anniversary-book-and-sleeve-pendants.jpg

- : https://www.jewellerybusiness.com/wp-content/uploads/2018/02/Spaceship-ornament-closed-2.jpg

- [Image]: https://www.jewellerybusiness.com/wp-content/uploads/2018/02/Spaceship-ornament-open.jpg

- [Image]: https://www.jewellerybusiness.com/wp-content/uploads/2018/02/Spaceship-ornament-closed-2.jpg

- [Image]: https://www.jewellerybusiness.com/wp-content/uploads/2018/02/West-Coast-Bear-belt-buckle.jpg

- [Image]: https://www.jewellerybusiness.com/wp-content/uploads/2018/02/Sterling-silver-and-18-K-little-league-rings.jpg

- [Image]: https://www.jewellerybusiness.com/wp-content/uploads/2018/02/Sterling-and-gold-coin-pendant-Studio-Jewellers.jpg

- [Image]: https://www.jewellerybusiness.com/wp-content/uploads/2018/02/JBD-Llyn-Strelau-Portrait-5-x-5-150x150.jpg

Source URL: https://www.jewellerybusiness.com/general/scintillating-silver-white-metal/